#EnhancedConnectivity – Monitoring rotating equipment

Lecture

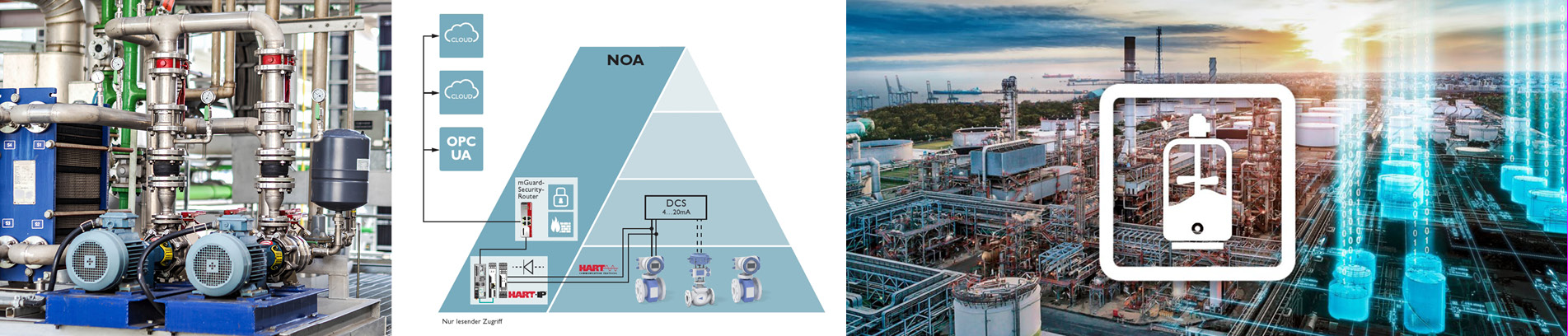

Rotating equipment is the primary cause of unplanned downtime. A pilot system at BASF Schwarzheide is being used to demonstrate the application of the NOA concept to large-scale mixing plants for early detection of potential failures. In the oil and gas industry we find rotation equipment upstream, midstream as well as downstream normally as pumps. Here the monitoring of the rotating equipment is a pre-condition to avoid down times. Predictive maintenance is the key word here.

Key Takeaways

- Following newest NAMUR trend “NOA”

- Technology update for brownfield sites

- Safe “side channel” for older plants

- Monitoring of sensitive agitators

- Using comfortable tools like Matlab in PLCnext

- Complex models but easy handling